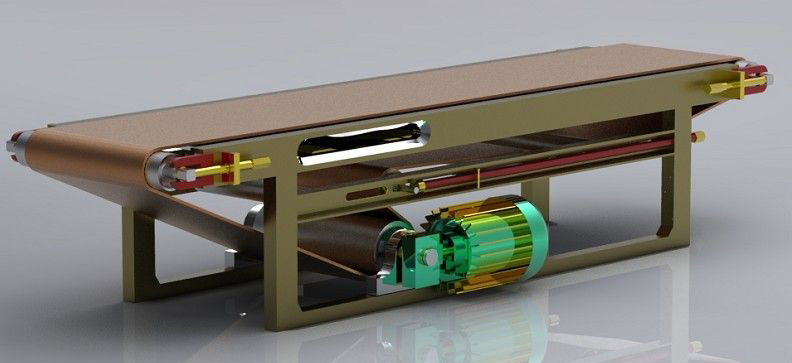

Working principle: The conveyor belt is tensioned by the driving device, and the middle frame and the idler roller constitute a conveyor belt as a traction and bearing member, thereby continuously conveying the scattered materials or pieces. Belt conveyors are also called belt conveyors or belt conveyors.

It is an economical logistics conveying equipment that is indispensable for the formation of rhythmic flow lines. Belt conveyors can be divided into heavy belt conveyors (such as mining belt conveyors) and light belt conveyors (such as in electronic plastics, food light industry, chemical and pharmaceutical industries, etc.) according to their conveying capacity.

The belt conveyor has strong conveying capacity, long conveying distance, simple structure and easy maintenance, and can easily implement program control and automation. The belt conveyor uses continuous or intermittent movement of the conveyor belt to transport items below 100KG or powdery or granular items. It runs at high speed, is stable, has low noise, and can be transported up and down.

WeChat

WeChat WeChat

WeChat