With the extensive development of the machinery industry, conveyor belts are more and more widely used. In the face of a wide range of conveyor belts on the market, the bosses of many machinery manufacturers do not know how to choose, and they are often distressed because the purchased conveyor belts are inappropriate.

The boss of many machinery manufacturers fed back that the belt used before often cracked, broken and not durable.

So why do conveyor belts have these problems?

1. There is a problem with the material of the conveyor belt. There is no distinction on the surface of the conveyor belt, but if the raw materials of some conveyor belts fail to pass the standard, the belt will be chapped and broken

2. Due to the lack of hot pressing and cold pressing time of vulcanization in the manufacturing process of conveyor belt, the tensile force of belt will be affected. If the tensile force is small, cracking and fracture will occur to a certain extent.

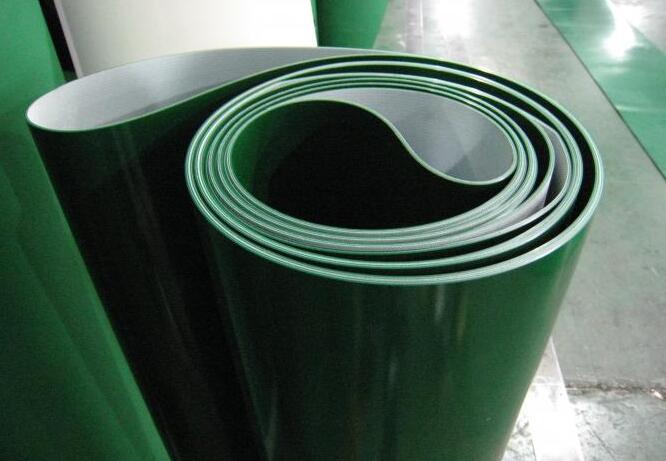

Miou belt focuses on the production, processing and sales of industrial conveyor belts. It has always provided customers with high-quality conveyor belts. It can be customized according to the material, width, height and perimeter required by customers. New and old customers are welcome to customize.

WeChat

WeChat WeChat

WeChat