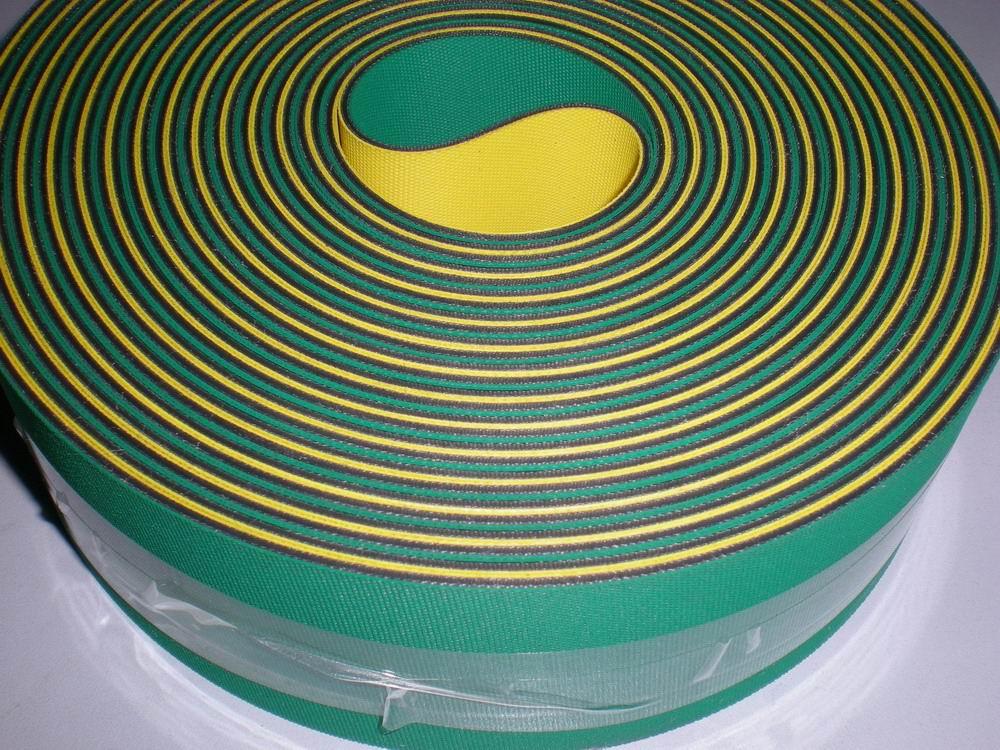

Nylon baseband is often used in the production of the drive belt, generally in the temperature between - 10 ℃ ~ + 60 ℃ normal use. So, how to keep nylon baseband? Keeping a good baseband can make it live longer and make more profits for enterprises. Next, nylon baseband manufacturers for you to introduce nylon baseband in the use of storage should pay attention to.

1. Nylon sheet base drive belt is made of high-strength nylon sheet base as tensile layer and wear-resistant leather or rubber. It is necessary to avoid direct sunlight when keeping it, and place it in the dark place as far as possible, more than half a meter away from the ground, and it is appropriate to spread horizontally naturally. It is strictly forbidden to deform under pressure.

2. Please install the belt pulley according to the marked pulley surface, running direction arrow and tension mark to ensure the parallelism of the pulley.

3. The standard elongation of the drive belt is 1.8%. After the tension is operated for 2-3 minutes, after the average distribution of the tension force, stop the machine to measure whether the tension mark still maintains the original tension range, and then make up the full according to the situation.

4. In order to make the life longer, the rotating body can be inserted in the cross part of the drive belt.

5. The rotating type of drive belt pulling device is conducive to extending its life. Please install the moving device in the position before the belt enters the passive wheel.

6. The drive belt is resistant to various oils, grease and other general chemicals, but it is not resistant to corrosion of concentrated organic acid, inorganic acid, phenol and alcohol. Please note.

7. The drive belt is normally used between -10 ℃ and +60 ℃.

8. For more details, refer to the technical parameters table.

The above is about the introduction of "the precautions for the use of nylon baseband in the custody and use". I hope that the staff can pay attention to the use of nylon baseband after understanding.

WeChat

WeChat WeChat

WeChat