Wood has played an important role in human beings since ancient times. TV cabinets, beds, office tables and chairs, chopsticks and so on all need wood. In the past, wood was transported manually, but now it can be transported by car. The conveyor belt in the woodworking industry is used in the process of polishing. What are the requirements of wood processing on the conveyor belt of polishing machine?

1、 The raw materials of conveyor belt in wood industry are divided into PVC and rubber. PVC is light conveyor belt, while rubber is heavy conveyor belt. It is also commonly used in coal, ore and other occupations, and the price is more expensive than PVC. According to the customer's response, PVC raw materials are suitable for the public, the quality is good, and the price is close to the people.

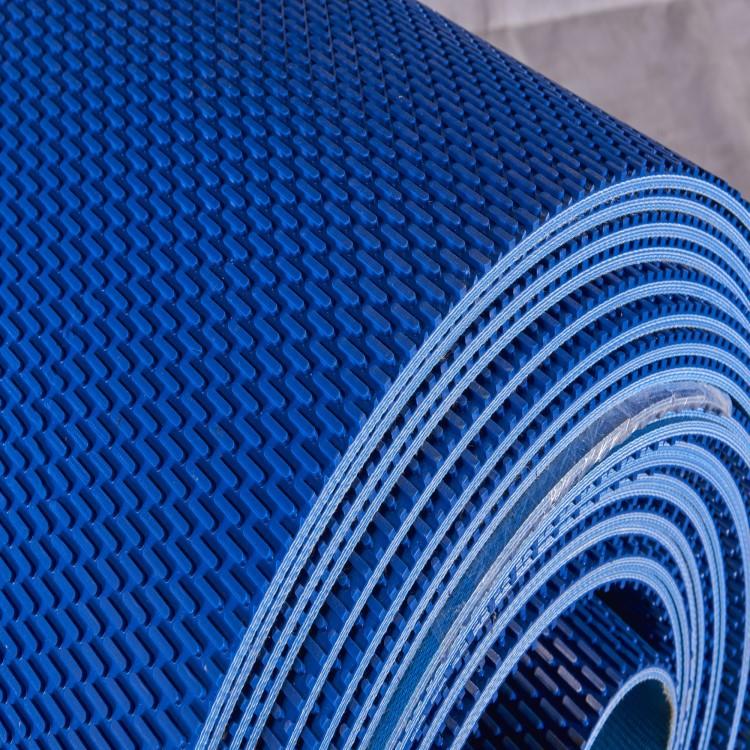

2、 The PVC conveyor belt in the wood industry has special requirements for customized stripes and added friction. The professional conveyor belt of wood industry will customize stripes on the surface to avoid the situation that the wood moves and the belt does not move. The commonly used stripes are diamond lattice stripes (marbling) and straight line stripes. I-shaped sand thick wood board quality is good, high friction, but in the thin sand wood, gypsum board will leave a slight sand mark. The diamond lattice will not have these problems, that is, the friction is worse than the straight type. These two kinds of thickness are all 9mm. There are grass stripes, golf stripes, with the thickness of 5mm and 7mm.

3、 There is also a woodworking industry belt is sanding machine belt. Sanding machine belt, in fact, is sanding machine conveyor belt, PVC conveyor belt or rubber conveyor belt, and it is still seamless circular conveyor belt. When wood processing, it is placed on the sanding machine. In the sanding and other wood processing process, the wood should move with the leather belt. If the friction is not enough, the conveyor belt will move forward by itself, but the wood will not move, which will play an important role Not to the intention of Sandwood. Secondly, the hardness of the special conveyor belt for wood should be appropriate. If it is too hard, it is difficult to load the belt into the sander. The softer belt will affect the service life.

The above is about the woodworking industry conveyor belt related knowledge introduction, hope to help you. Welcome new and old customers to inquire.

WeChat

WeChat WeChat

WeChat